Friday, December 31, 2010

Wednesday, December 29, 2010

Wednesday, December 22, 2010

Boll Aero 1.8

Tom,

My latest effort from a 3 part article in the British magazine AMI. Designed by Chris Boll. it is called the Boll Aero 1.8. Not too

difficult to build with basic machine skills. Test running will have to wait until after the holidays.

Merry Christmas

Dave Acton

Update: It runs!

Tuesday, December 7, 2010

Thursday, December 2, 2010

Sunday, November 28, 2010

Wednesday, November 24, 2010

Monday, November 22, 2010

Sunday, November 21, 2010

Jivaro Models (French)

Jivaro-models.org features some photos

and plans of some unorthodox looking models.

Such as Eut Tileston's Sylph.

And a model of a plane I used to fly that I would never have thought I would see in miniature.

Friday, November 19, 2010

Tuesday, November 16, 2010

Cleveland Cloudster 900 - More on Fuselage-Stab Interface

Electric Cloudster 900 Project

The information in this report presents a series of details that may not be of interest some of you, but it is necessary for documentation purposes.

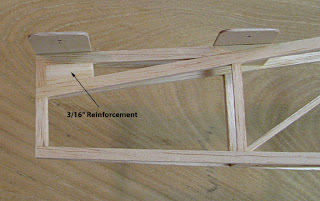

A 3/16" piece was glued in under the stab's rear plywood support on each side to reinforce the single vertical post as shown below.

Two additional 3/16" blocks were glued in between the top longerons under the stab's front plywood support as shown below. This ties the front support solidly to the longerons.

In this top view, you can also see the "V" block under the rear support. Notice that the blocks extend out beyond the plywood supports and will serve as a shelf or ledge to glue the top 1/16" sheet planking to.

A fuselage transition (or fairing) is required in front of the stab' leading edge. This was made out of 1/4" soft balsa and the back face was lined with 1/64" plywood veneer as shown below. The picture below shows the completed stab platform on the rear of the fuselage, which includes the top 1/16" sheet flush planking and the fuselage transition on the front. This fuselage platform provides a really nice interface for the stab to fit on to.

The next detail to be addressed is the small fairing at the base of the fin's leading edge. A piece of 1/4" sheet balsa was cut out and glued in place as shown below.

The outline of the piece was then cut and sanded to fair into the stab leading edge point as shown below. The actual shaping will be done when the leading edge of the fin is trimmed and shaped.The last detail in this series was the third hinge to complete the rudder's three hinge support. This was installed just below the rudder's control horn plywood base as shown below.

The location of the rudder's bottom hinge requires a hinge half in the fuselage's rear tail post near the bottom as shown below. Notice that a box was made to cover the hinge tongue protruding through the tail post.The picture below shows the rudder's third hinge pinned in place........................

Cleveland Cloudster 900 - Fuselage-Stab Interface Continues

Electric Cloudster 900 Project

After the Cloudster 900 dried overnight in the jig set up, the four 4-40 screws were unscrewed and the stab removed. This left the two 1/16" plywood mounting plates firmly glued in place on the fuselage and exactly aligned with the mounting holes in the stab itself as shown below.

Cleveland Cloudster 900 - Fuselage/Stab Interface

Electric Cloudster 900 Project

We had an early dinner this evening, which provided me with the opportunity to mate the stab with the fuselage. I cut two idenical stab mounting plates out of some good 1/16" Birch plywood. These plates are 1.25" wide and 3.20" long. Matching holes were drillied for 4-40 Allen head screws as shown below. In addition, 0.22" diameter holes were drilled to match the locations of the two 2-56 Cap screws and washers used to secure the fin as shown below. These holes permit the stab to fit flush on the plates with fin in place.

The fuselage was turned upside down and the two top longerons under the wing saddle were weighted down on balsa blocks with three steel squares resting on two 1/4" steel rods as shown below. Notice the fuselage sides were checked for squareness with the carpenter's square as shown below. This set up established the reference plane for mounting the stab.

The stab with the mounting plates attached was also turned upside down and placed on a large balsa block shown below. A series of measurements were made to position the stab for gluing. The straight bottom of the stab rear spar was measured on each side relative to the work table be sure the it was parallel to the plane of the work table. Then diagonal measurements from the rear tips of the stab spar up to the front corners of the fuselage were made and adjustments were made until both diagonals were equal. Then the two plywood mounting plates were carefully marked along the outside of the longerons. The stab was removed and aliphatic glue was applied to the plate's contact areas.

hen the stab was again placed upside down on the large balsa block and carefully realigned. The excess glue was wiped off inside and out with a wet Q-Tip. A 1/4" plywood piece was placed on the bottom longerons over the stab plates and a small steel vise was placed on the plywood piece as press to apply pressure between the top longerons and the stab plates. A close up of this jig set up is shown below. This will be left to dry overnight.....................Cleveland Cloudster 900 - Horizontal Tail Hinge Wire Retention

Electric Cloudster 900 Project

Today was spent working through a hinge wire retention system that connects the elevator hinge halves to the stab hinge halves of the horizontal tail. Earlier it was said that the hinge piano wire was .032" in diameter, which turned out to be wrong. Instead the hinge wire is .033" in diameter. A DuBro hinge shown below was selected because the .033" wire was a force fit in the .031" hinge loops. One of the loops was cut off as shown below.

The other loop on the DuBro hinge was also cut off, but a small tongue was left on the bottom as shown below.

The removable stop's friction fit was tight enough to hold on the hinge wire, but loose enough to slide onto the wire with a little pressure as shown below. After the tapered end of the hinge wire is inserted through all of the hinges, the 3/32" edge of an a metal plate is placed up against the blunt end of the wire. Then the removable stop is pushed on the end of the tapered wire. The back of a No. 11 X-Acto blade is then butted up against one side of the removable stop and slid down along the side of the wire until the removable stop contacts the outer edge of the hinge half, thus trapping the hinge wire between the two outside hinges as shown below. This is a very simple and functional way to hold the continuous hinge wire in place.........................

Cleveland Cloudster 900 - Completing the Horizontal tail

Electric Cloudster 900 Project

After three full days of adding balsa filler blocks, gussets, trimming, sanding, and shaping, the horizontal tail was finally finished this evening. The first step was to cut out and glue some soft balsa filler blocks on top of the stab and elevator tip pieces as shown below. You can see part of the elevator in the upper right had corner of the picture.

This picture is a close up of the balsa filler on the left tip of the stab. The inside edge of the filler block is trimmed and sanded to match the inside edge of the tip piece before it is glued on. The outside edge is only roughed in because it can be easily trimmed and sanded later.

Soft balsa filler blocks were also added to the top of the elevator pieces that glue to V members as shown below.The picture of the bottom of the stab below shows the three gussets that tie the 1/8" X 1/4" spar to the leading edge. Also 1/16" gussets were added to all of the elevator's rib/TE joints to reinforce the joints.

This picture of the finished horizontal tail says it all! Notice the four tip gussets that tie the tip pieces to the hinge line spars of the stab and the elevator. A single piece of .032" piano wire 36" long is use to pin the hinges together.

Light wood was carefully chosen to keep the weight of the horizontal tail at a minimum. As shown below, the completed horizontal tail structure only weighs 63 grams (2.2 oz)...........................

Subscribe to:

Posts (Atom)